Service

08:00~24:00(Beijing)

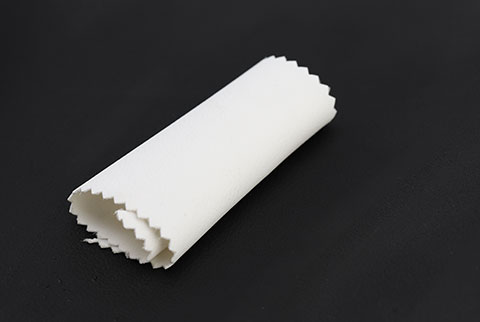

Silicone Leather

manufacturer from China

Refuse to kill, beautiful special silicone leather in harmon

In March this year, a new silicone leather quietly on the market, can replace leather silicone leather, with weather resistance, flame retardant, antifouling easy to care, skin-friendly not sensitive, anti-mildew antibacterial, wear durable, safe and non-toxic and other characteristics, it has the characteristics of leather, but do not need to kill animals like leather, It is widely used in sofa, wallpaper, non-slip carpet, gloves and other products, and gives them excellent performance, such as skin touch and excellent appearance.

For a long time, people have been looking for a functional leather that is both environmentally friendly and durable. Merite silicone leather manufacturers provide this option. Merite creatively coats silicone materials for baby pacifiers on a variety of environmentally friendly substrates. With the traditional PU, PVC leather need to add a variety of chemical additives to improve feel, wear resistance, weather resistance and other properties, beautiful special from the beginning of the design to abandon the use of various chemical additives.

In this embodiment of the performance of leather material itself, we found that UMEET silicone leather besides high safety coefficient, no sensitization characteristics, also provides top like skin delicate touch, at the same time in the hydrolysis resistance, UV aging resistant, flame retardant, easy to clean, compared to conventional on market in such aspects as chemical reagent of leather has many natural advantages.

Natural stain resistance

"UMEET" with innate antifouling, for the vast majority of pollutants can be easily removed with water or detergent, and leave no traces, greatly saving the internal and external decorative materials cleaning time and reduce the difficulty of cleaning, to meet the modern simple and fast life concept.

Natural environmental protection

All leather of "UMEET" adopts the most advanced dry normal process, and refuses to use organic solvents and chemical additives in the production process, thus ensuring that "UMEET" leather products have lower VOCs release and safer performance.

Natural flame retardant

Although the use of flame retardants has played a good role in fire prevention and fire retardation, many recent studies show that the abuse of chemical flame retardants has caused serious pollution of water body and environment, and also threatened human health. "EMEET" refuses to use flame retardants and does not add any flame retardants. We easily pass the following flame retardants test:

Natural chemical resistance

In the process of high frequency disinfection and cleaning in hospitals, schools and other public places, our leather can resist various detergents and disinfectants. Alcohols, hypochlorous acid, hydrogen peroxide and quaternary ammonium salts commonly used in the market will not affect the performance of "graceful" leather.

In recent years, the domestic silicone leather industry continues to rise, with UMEET as an example. As an all-natural silicone leather research and development unit, With 35 years of rich experience, with 100% silicone as raw material, has formed from silicone raw material synthesis production to silicone fabric composite one in place of the industrial chain, become the world's leading silicone leather development and manufacturer. Its use of solvent-free production process, long-term use of non-toxic harmless, VOC release is far less than the national mandatory standards. In 2021, with the expansion of the international standard chemical plant and the comprehensive renewal of the production line, UMEET is closer to becoming the world's largest organic silicon fabric production base.