Service

08:00~24:00(Beijing)

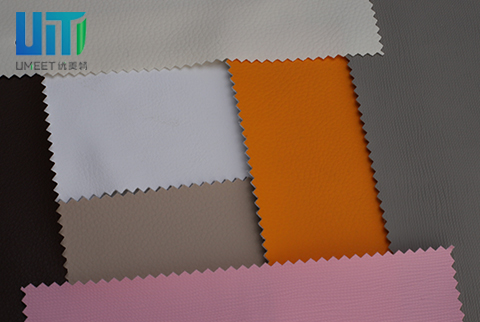

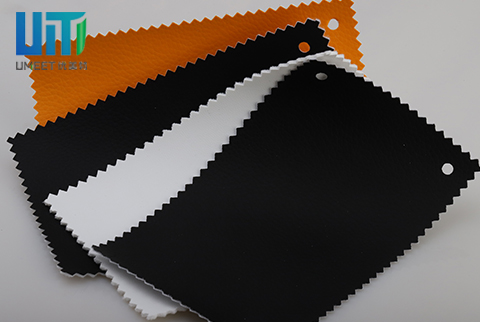

Silicone Leather

manufacturer from China

Silicone leather is a new type of environmentally friendly leather, with silica gel as the raw material, this new material and microfiber, non-woven fabric and other substrates, the combination of processing and preparation, suitable for a variety of industry applications. Silicone leather is made of solvent free technology by coating and bonding silicone on various substrates. It belongs to the new material industry of the 21st century.

Organic silicone rubber has always been regarded as the most trusted green product due to its good biocompatibility in both the production process and the use process. It has been widely used in the preparation of baby pacifiers, food molds and medical devices, all of which reflect the safety and environmental protection characteristics of silicone rubber products. In addition to safety and environmental protection issues, what are the advantages and disadvantages of silicone leather (silicone leather) compared with traditional PU/PVC synthetic leather? So let's see

Advantages of silicone leather:

Excellent wear resistance: 1KG roller 4000 cycles, no cracks on the leather surface, no wear;

Organic silicon waterproof, antifouling sex: leather surface with low surface tension, fouling resistance level to 10, with water or alcohol can be easily removed, the sewing machine oil in life, instant coffee, tomato sauce, blue ballpoint pen, ordinary soy sauce, chocolate milk and other stubborn stains, and will not affect organic silicon leather performance;

Excellent weatherability: silicone leather has strong weatherability, which is mainly shown in hydrolysis resistance and light resistance;

Hydrolysis resistance: through more than ten weeks of time test (temperature 70±2℃, humidity 95±5%), the leather surface is not sticky, shiny, brittle and other degradation phenomenon;

Light resistance (UV) and good color fastness: excellent performance in resisting fading of sunlight exposure for ten years, still maintain its stability, color unchanged;

Combustion safety: combustion does not produce toxic products, and organosilicone material itself has a higher oxygen index, without adding flame retardant can reach a higher flame retardant level;

Superior processing performance: easy to fit, not easy to deform, small fold, easy to shape, fully meet the processing requirements of leather applications;

Cold crack resistance test: silicone leather can be used in -50°F environment for a long time;

Salt spray resistance test: after 1000h salt spray test, silicone leather surface has no obvious change.

Disadvantages of silicone synthetic leather:

1. Leather surface strength is slightly weaker than PU synthetic leather;

2. The price of raw materials is slightly expensive.

The article comes from the Umeet silicone leather, reprint please indicate the source!