Service

08:00~24:00(Beijing)

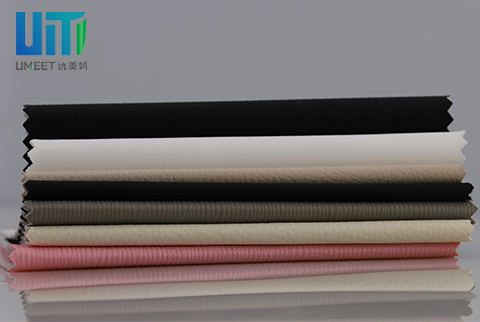

Silicone Leather

manufacturer from China

With the improvement of the quality of life, people's demand for leather is increasing. The reason why leather products have been favored by people for thousands of years is mainly its superior and irreplaceable performance, as well as the ability of leather upgrading and innovation. The following beautiful special inventory with you a few big types of leather.

One: leather

Dermal leather is made of animal skin coated with polyurethane (PU) or acrylic resin, which is conceptually different from artificial leather made of chemical fiber materials. The dermis said on the market is generally the first layer of skin, two layers of skin, synthetic skin one of three, mainly based on cowhide. The main characteristics are breathable, comfortable feel, strong toughness; Smell big, easy to change color, nursing difficult, easy hydrolysis.

Two: PVC leather

PVC leather, also known as PVC artificial leather, is coated on the fabric with PVC, plasticizer, stabilizer and other additives made of paste, or then covered with a layer of PVC film, and then processed by a certain process. The main characteristics are easy to process, wear resistance, aging resistance, cheap; The air permeability is poor, the low temperature becomes hard and brittle, the high temperature becomes sticky, the large use of plasticizer hurts the human body and the pollution is serious, the peculiar smell is big, so it is gradually abandoned by people.

Three: PU leather

PU leather, also known as polyurethane synthetic leather, is made of fabric coated with PU resin. The main characteristics are comfortable feel, close to leather, mechanical strength, design and color, wide range of applications; Not wear-resistant, almost impermeable to air, easy to be hydrolyzed, easy to delamination and packaging, high and low temperature crack surface, the production process pollute the environment

Four: microfiber leather

The substrate of the microfiber leather is microfiber, and the surface coating composition is mainly polyurethane (PU) or acrylic resin. It is characterized by good hand feel, good finalization, strong toughness, good wear resistance, good uniformity, good fastness to folding; Easy to damage, not environmental protection, airtight, poor comfort.

Five: silicone leather (half silicon)

Most semi-silicon products on the market are coated with a thin layer of organosilicone on the surface of solvent-free PU leather, which is strictly PU leather. However, after coated with organosilicone layer, the leather's easy cleaning and water resistance are greatly enhanced, and the other features are still PU.

Six: silicone leather (all silicon)

Silicone leather is a kind of synthetic leather products which can be used instead of real leather in appearance and feel. It is usually made from a fabric base coated with 100% silicone baby pacifier material. Silicone leather has no peculiar smell, hydrolysis resistance, weather resistance, environmental protection, easy to clean, high and low temperature resistance, acid, alkali and salt resistance, light resistance, heat aging resistance, yellowing resistance, bending resistance, can eliminate toxicity, strong color fastness and other advantages. It can be used in outdoor furniture, yacht, ship, flexible packaging decoration, automobile interior decoration, public facilities, sporting goods, medical equipment and other fields.

As people living standard unceasing enhancement, also increasingly demand for quality of life, more environmental protection new materials are used by mining, the organic silicon industry chain is more collective wave red, all kinds of silicone leather market unceasingly, the beautiful, science and technology co., LTD., as all natural silica gel leather research and development unit, with rich experience, With 100% organosilicon as raw material, it has formed an integrated industrial chain from the synthetic production of silicone raw materials to the composite of silicone leather fabric, and has become the world's leading development and manufacturer of silicone leather. Its use of solvent-free production process, long-term use of non-toxic and harmless, VOC emission is far less than the national mandatory standards. In 2018, the expansion of the international standard chemical plant and the comprehensive update of the production line, silicone leather is to become the world's largest silicone fabric production base target closer.